Resources

Arabesque is highly skilled work force can handle any major time bound project with precision and superior finish.

LABORATORY

The test for flexural strength is the most important way of assessing the quality of GRC. Power-Sprays supply a range of flexural testing equipment. Arabesque GRC have well equiped testing machineries and efficient workers to maintain quality of our products.

FACTORY

Arabesque has well built-up factory in st.no 41 Industrial Area. It comprises 2000 m2 covered production area with semi automatic batch plant, a high humidity curing and QC Laboratory all serviced by overhead gantry cranes. Production is split between cast elements which are compacted on vibrating tables and had spray for the lightweight cladding elements. Precast concrete and glass fiber reinforced with workforce of more than 125 nos skilled /semi skilled persons, 30 nos of operators and labours are also included in the workforce.

MOULD SHOP

All moulds in Rubber, GFRP, Gypsum, Timber and Steel are manufactured in the built-up workshop of 600m2 area which is equipped with the latest timber and metal fabrication machinery and plant. All brackets, special firings and structural steel works in stainless steel and rolled sections required by Arabesque are manufactured in addition mould making timber carving.30 No.s highly skilled carpenters are employed in Mould shop.

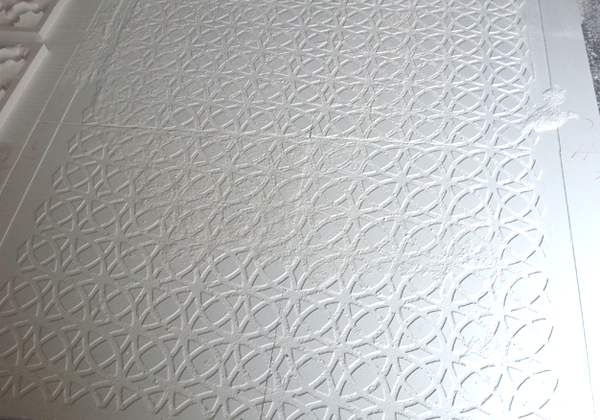

CNC DESIGN SHOP

Our work range includes decorative motives for doors, wall paneling, ceiling and so many designs which can be customised as per clients request. Workshop equipped with FLEXICAM 3 & 4 Axis machine, leader in GRC Design world.

PAINT SHOP & MIXING UNIT

The multi-component mixing unit is an important part of our paint & mixing shop. The mixing ratio of the components must be continuously monitored and adjusted. Therefore, we have designed and collaborated with international suppliers to own 2K-/3K- mixing unit with automatic color exchange from standard components.Also using silica and imported sands from Turkey, India and different parts of the world to get a quality finish.

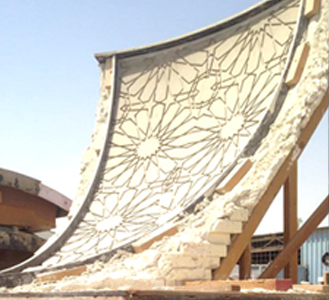

MATERIAL INSTALLATION

All the GFRC, GFRG, PCC and GFRP material installation works are followed with appropriate safety norms by highly skilled work force of 145 nos which includes Site Foremen, Skilled and semi skilled persons. Site Department has all types of modern handy equipment facilities to carry out all the installation activities on Site.